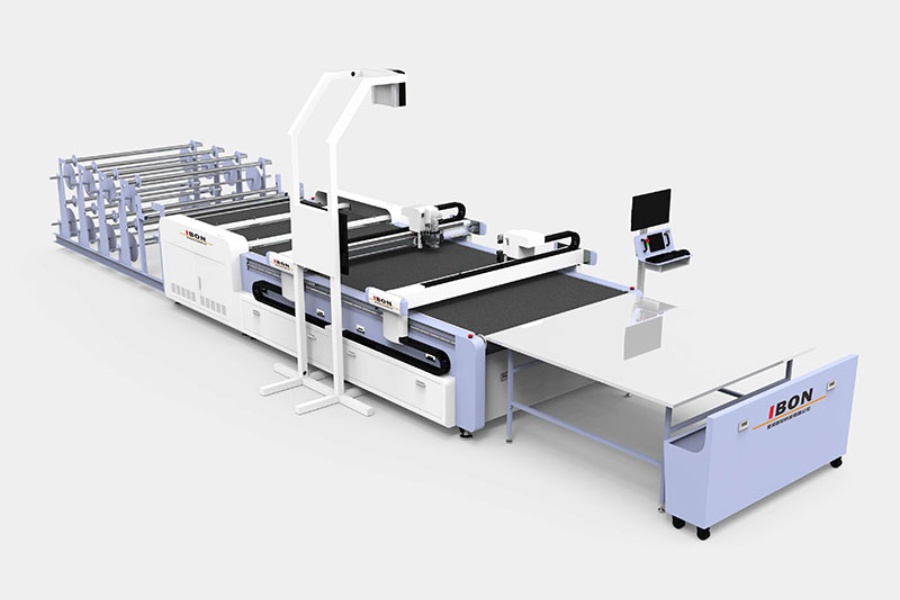

IBON home textile cutting machine: Leading the innovation of cutting technology in the luggage industry

Publish Time: 2024-11-13

In the production process of the luggage industry, cutting is a crucial link. The traditional manual cutting method is not only inefficient, but also difficult to ensure cutting accuracy, which is a huge challenge for luggage companies pursuing high-quality and efficient production. However, with the advancement of science and technology and the development of intelligent equipment, IBON home textile cutting machine is leading the innovation of cutting technology in the luggage industry with its excellent performance and intelligent characteristics.1. Technical features of IBON home textile cutting machineHigh-precision cutting: IBON home textile cutting machine adopts advanced cutting technology to ensure the accuracy and consistency of cutting, greatly improving the quality and aesthetics of luggage products.Intelligent identification and nesting: The equipment has the function of intelligently identifying the contour and defects of leather materials, can automatically avoid defects, and intelligently nest materials according to the outer contour to maximize material utilization and reduce waste.Efficient and automated production: IBON home textile cutting machine supports high-speed, automated cutting and marking processes, which can greatly improve production efficiency and reduce labor costs and labor intensity.Wide applicability: The equipment is suitable for cutting a variety of luggage materials such as leather, PU, polyester, canvas, cotton, linen, silicone, etc., to meet the diverse production needs of luggage companies.Easy to operate and maintain: The operating interface of the IBON home textile cutting machine is simple and clear, and it is easy to operate; at the same time, the maintenance of the equipment is also very convenient, and only needs to be regularly checked and replaced with worn parts.2. The impact of IBON home textile cutting machine on the luggage industryImprove product quality: Through high-precision cutting and intelligent recognition functions, IBON home textile cutting machine can ensure the cutting accuracy and consistency of luggage products, thereby improving product quality and meeting consumers' demand for high-quality luggage.Improve production efficiency: Efficient and automated production methods enable luggage companies to significantly improve production efficiency, shorten production cycles, and quickly respond to market demand.Reduce production costs: Intelligent recognition and nesting functions can maximize material utilization and reduce waste, thereby reducing production costs and improving corporate profitability.Promote intelligent upgrading: The application of IBON home textile cutting machine has promoted the intelligent upgrading of the luggage industry, enabling luggage companies to better adapt to the development trend of intelligent manufacturing and enhance the competitiveness and sustainable development capabilities of enterprises. IBON home textile cutting machine is leading the innovation of cutting technology in the luggage industry with its excellent performance and intelligent characteristics. Its application not only improves the quality and production efficiency of luggage products, but also reduces production costs and promotes the intelligent upgrading of the industry. With the advancement of science and technology and the continuous expansion of the market, IBON home textile cutting machine is expected to play a more important role in the luggage industry and contribute more to the prosperity and development of the industry.In short, IBON home textile cutting machine is a major innovation in the cutting technology of the luggage industry. It brings more efficient, smarter and more environmentally friendly production methods to enterprises, helping luggage enterprises to achieve high-quality development.

IBON home textile cutting machine is leading the innovation of cutting technology in the luggage industry with its excellent performance and intelligent characteristics. Its application not only improves the quality and production efficiency of luggage products, but also reduces production costs and promotes the intelligent upgrading of the industry. With the advancement of science and technology and the continuous expansion of the market, IBON home textile cutting machine is expected to play a more important role in the luggage industry and contribute more to the prosperity and development of the industry.In short, IBON home textile cutting machine is a major innovation in the cutting technology of the luggage industry. It brings more efficient, smarter and more environmentally friendly production methods to enterprises, helping luggage enterprises to achieve high-quality development.